The PPGI/PPGL production process is quite complicated and includes many steps. Next, let's learn about the production process with ZEBRA Steel to produce PPGI/PPGL. The PPGI and PPGL production process includes the following steps:

Material checking: Raw materials are carefully inspected before entering the production process.

Surface finishing treatment: Steel needs to be cleaned to remove impurities and dirt, this is an important step to ensure the coating will adhere tightly to the product surface.

Galvanized coating or galvalume coating: Once the surface has been cleaned, the steel is put through a galvanized or galvalume process. This plating layer has the effect of limiting corrosion of the product, helping to protect the product surface to the maximum.

Anti-corrosion coating: After being coated with galvanized or galvalume, another anti-corrosion layer, usually a paint layer combined with antioxidants, is applied to the surface.

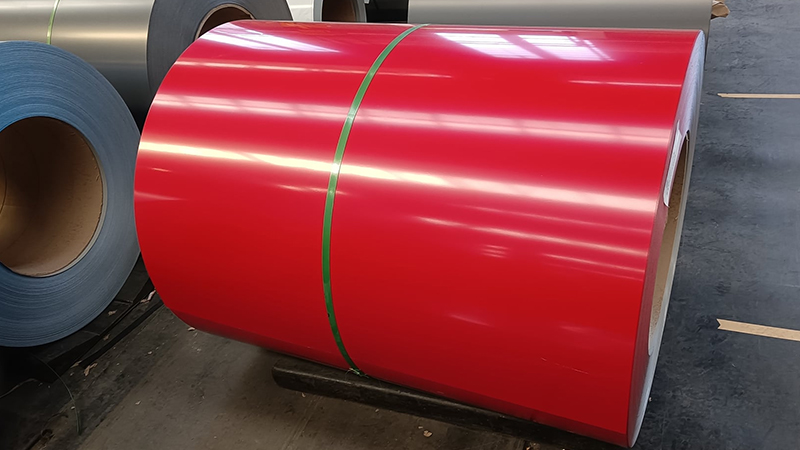

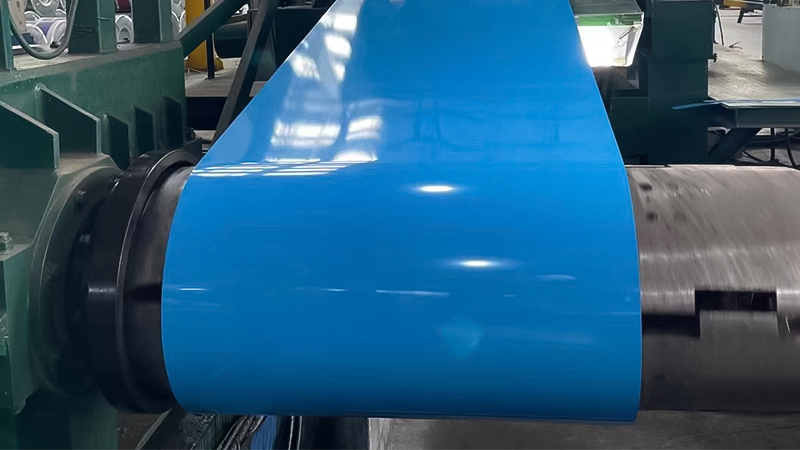

Color coating: A color coating layer is applied to the plated and anti-corrosion coated surface. This process can be done using roll or spray painting methods.

Collecting coils: After the color coating has been completed, the steel will be put into the furnace to dry the paint layer, then check and collect the coils.

Each type of material has its own advantages and disadvantages. To know why PPGI/PPGL is widely used in daily life, please join MRS Steel to learn about the advantages of PPGI and PPGL through the section below.

Corrosion resistance: PPGI/PPGL products are highly corrosion resistant thanks to being plated with a layer of galvanized or galvalume on the product surface. For particularly corrosive environments, PPGL is preferred over PPGI.

High aesthetics: Pre-painted/Color coated steel has quite high aesthetics because it is painted in many colors and patterns depending on the user needs. From there, it also contributes to increasing the aesthetics of your project.

High durability: In addition to being plated with an additional layer of paint to make the product more beautiful, PPGI/PPGL is made from galvanized steel and galvalume steel; these two materials are quite resistant to corrosion. This helps increase the durability of the product. Under normal conditions, the lifespan of PPGI and PPGL can last up to 50 years.

Pre-painted/Color coated steel is commonly used in the construction industry. However, in addition to construction, PPGI/PPGL is also used in many different industries due to its durability, corrosion resistance and aesthetics. Below, join ZEBRA Steel to learn about the applications of PPGI and PPGL.

Construction industry: PPGI/PPGL are often used as roofing sheets, partitions and wall cladding for buildings and structures. The material durability, corrosion resistance and aesthetics make it an attractive choice for architects and construction companies.

Automobile industry: For the auto industry PPGI and PPGL is used in the production of car bodies, spare parts and other auto components. The material rust resistance makes it ideal for the harsh conditions of the automotive industry.

Electrical industry: PPGI/PPGL color coating is used in the production of electrical appliances and devices such as refrigerators, air conditioners and washing machines. The material smooth surface and corrosion resistance make it ideal for these types of applications.

Furniture industry: For some furniture products that require sturdiness and aesthetics, this will be the top choice. Especially projects and products The material ability to withstand the elements and its attractive appearance make it a popular choice for furniture manufacturers.

Packaging industry: PPGI/PPGL is used in the production of cans and other packaging materials. The material corrosion resistance and strength make it ideal for packaging applications.

English

English