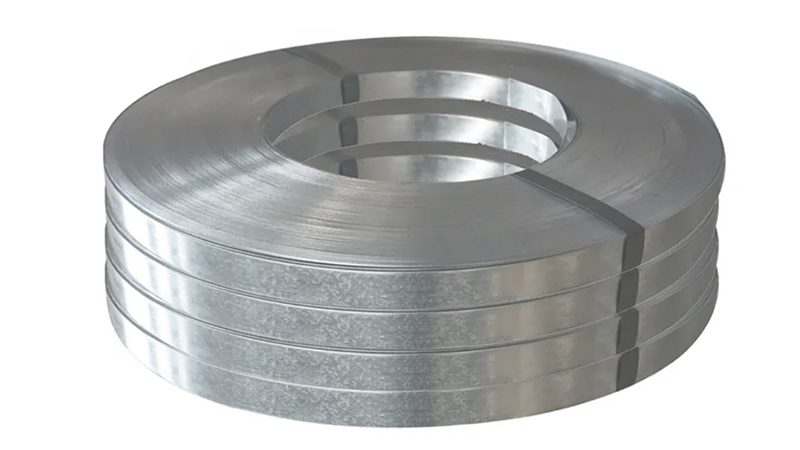

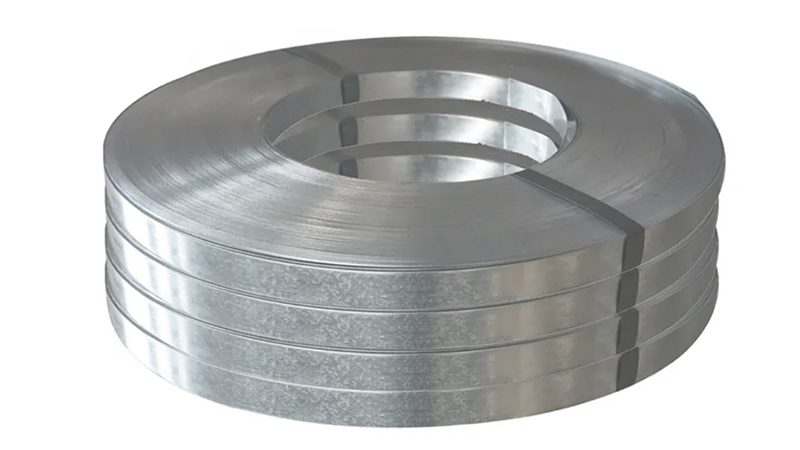

Slitting Steel Strip is the process of processing wide strip steel into narrow strip steel through longitudinal cutting, which is widely used in various industrial fields.

The following are its commonly used sizes, thicknesses, standards, and typical applications:

1. Common sizes and thicknesses

Thickness range:

Ultra thin tape: 0.05-0.2mm (precision electronics, foil materials)

Thin strip: 0.2-1.0mm (for household appliances and light industry)

Medium thickness strip: 1.0-3.0mm (mechanical structure, automotive)

Thick strip: 3.0-6.0mm (for heavy machinery and pipelines)

Width range:

Narrowband: 10-200mm (electronic components, hardware)

Medium broadband: 200-600mm (home appliances, building materials)

Broadband: 600-1500mm (car board, container)

Roll weight: usually 3-10 tons/roll, customized according to equipment capacity and requirements.

2. Implement standards

International standards:

ASTM AISI (American Standard): such as ASTM A653 (galvanized steel strip)

JIS G (Japanese Standard): such as JIS G 3312 (Galvanized Steel Strip)

EN (European standard): such as EN 10139 (cold-rolled narrow steel strip)

Chinese standards:

GB/T 708 "Dimensions, Shape, Weight and Allowable Deviations of Cold Rolled Steel Plates and Strips"

GB/T 3524 "Carbon Structural Steel Cold Rolled Strip"

GB/T 2518 "Continuously hot-dip galvanized steel sheet and strip"

Special standards:

Automotive industry: ISO/TS 16949 (Quality Management System)

Food packaging: GB 4806.9 (Hygienic standard for stainless steel tableware containers)

3. Main application areas

Home appliance manufacturing:

Refrigerator and air conditioner casing (galvanized steel strip, thickness 0.4-1.2mm)

Washing machine inner drum (stainless steel strap, thickness 0.5-1.0mm)

Automotive industry:

Body structural components (high-strength steel, thickness 0.8-2.5mm)

Seat rail (cold-rolled strip steel, thickness 1.2-3.0mm)

Electronic appliances:

Lithium battery lug (ultra-thin stainless steel, thickness 0.05-0.1mm)

Circuit board shielding cover (copper strip, thickness 0.1-0.3mm)

Building materials:

Light steel keel (galvanized strip steel, thickness 0.5-1.5mm)

Color coated plate substrate (hot-rolled pickled strip steel, thickness 0.3-2.0mm)

Hardware products:

Saw blade, blade (tool steel strip, thickness 0.5-3.0mm)

Fasteners (carbon steel strip, thickness 1.0-4.0mm)

4. Key points of slitting process

Material selection: Choose carbon steel, stainless steel, copper aluminum, etc. according to the purpose.

Tolerance control:

Thickness tolerance: ± 0.02 to ± 0.1mm (more stringent for precision applications)

Width tolerance: ± 0.1 to ± 0.5mm

Edge processing: laser cutting (high-precision), disc cutting (conventional), deburring (scratch resistant).

5. Special requirements

Surface treatment: Before slitting, it is necessary to confirm whether the coating (such as galvanizing, chrome plating) needs to be retained or coated with oil for rust prevention.

Packaging method: moisture-proof paper+steel coil corner protector (precision material), or simple packaging (industrial use).

By selecting appropriate sizes and standards, strip cutting can meet diverse needs from precision electronics to heavy machinery, with the key being to balance cost and performance based on application scenarios.

English

English