PPGI Prepainted Galvanized Steel Coil

样本:点击下载

Prepainted Galvanized steel Coil Manufacture

No cutting corners on quality and weight

Prepainted galvanized steel Coil(PPGI) Also known as color coated steel coil, is a type of sheet made of steel coil as the substrate, coated or laminated with various organic coatings or plastic films on the surface. Common substrates include cold-rolled sheets, galvanized sheets, galvalume sheets, high aluminum alloy sheets, and stainless steel sheets.

Production process:

Surface pretreatment: Chemical degreasing and chemical conversion treatment are applied to the substrate to enhance the adhesion of the coating.

Application of organic coating: Apply one or more layers of organic coating on the surface of the substrate.

Baking curing: Bake the coated board to cure the coating.

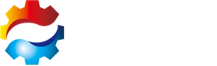

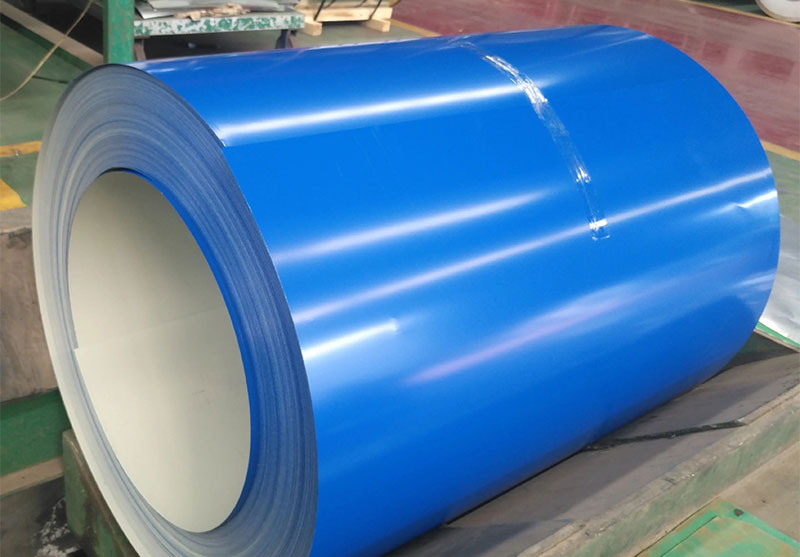

PPGI Steel Coil Color

Provide a full range of color options, or produce according to samples

Is that all? No! We have more varieties

PPGI Steel Coil Surface Include The Following Types

Smooth(Bright):

The surface is smooth and has a mirror effect, presenting a bright luster.

Matte(Smooth):

The surface does not have a significant mirror effect, presenting a soft luster.

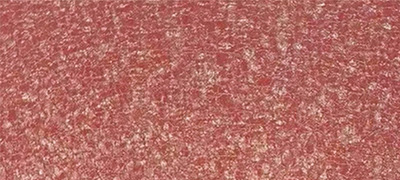

Matte(Wrinkled):

The surface is treated with a matte finish, giving it a rough texture and presenting a delicate sugar like effect.

Pattern:

The surface is embossed to present various patterns and textures, commonly including mesh, wood grain, stone grain, etc.

Please choose your favorite color and type according to your needs.

Please choose your favorite color and type according to your needs.

| Name |

Prepainted galvanized steel coil(PPGI Steel Coil) |

| Thickness | 0.12-2.0mm |

| Width | 600-1250mm |

| Zinc Coating | 20-275g/m2 |

| Front Painting | 10-35 microns or Customized |

|

Back Painting |

5-25 microns or Customized |

|

Coating Process |

Front:double coated & double drying Back:double coated & double drying,single-coated & double drying |

|

Coating types |

Top paint:PVDF,HDP,SMP,PE,PU Primer paint:Polyurethane,Epoxy,PE Back paint:epoxy.modified polyester |

|

Grade |

CGCC,CGCH,DX52D,DX53D,G550,DX51D |

|

Test Report |

Provided |

Prepainted galvanized steel coil

1.Lightweight texture: Due to its substrate being mostly metal coil, the overall weight is relatively light.2.Corrosion resistant and durable: The surface coating has good corrosion resistance, which extends the service life of the board.

3.Good decorative properties: The surface can be coated with various colors of paint, suitable for different decorative needs.

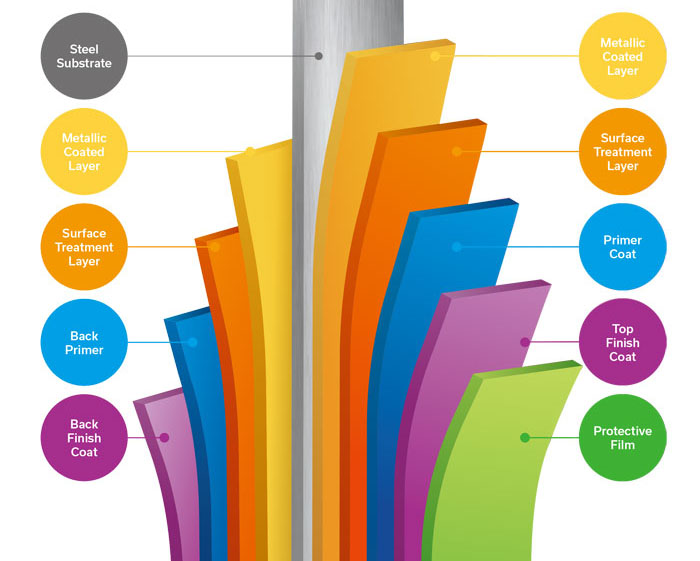

Prepainted galvanized steel Sectional

Base Metal (Galvanized Steel): The core of the coil is galvanized steel, which is steel coated with a layer of zinc to provide corrosion resistance.

Chemical Treatment Layer: This layer is applied to the galvanized steel to improve adhesion of the subsequent coatings and to enhance corrosion resistance.

Primer Coating: A primer coating is applied on top of the chemical treatment layer. This layer further enhances adhesion and provides an additional barrier against corrosion.

Topcoat (Finish Coat): The topcoat is a colored paint layer that provides both aesthetic appeal and additional protection.

Back Coat (Optional): On the underside of the coil, a back coat may be applied.

Product quality inspection

Width Test

Check whether the width of the steel coil is consistent with the contract agreement, with an error not exceeding 1%

Thickness Test

Using sampling methods and machine detection of thickness for more accurate data

Paint film thickness test

Use the eight point test method to measure the thickness of the front and back paint film

Impact resistance test

Take samples of the color coated board and conduct impact testing to check for any peeling of the paint film

- 1

艾能空压机种类、规格齐全

艾能压缩机是高效、品质卓越的,凭借雄厚的技术力量和丰富的制造经验,艾能螺杆压缩机品种及规格齐全,能够满足不同用户对气体品质、气量大小、使用工况等的不同要求,主要产品有:固定式螺杆空压机、双级压缩永磁变频空压机、变频空压机、永磁变频空压机、低压力螺杆空压机、工程用移动式螺杆空压机、蜗旋式螺杆空压机、矿用移动式螺杆空压机、无油螺杆空压机、无油中高压压缩机等等。对特种行业或特殊要求,艾能公司更擅长按照用户要求定制特殊的压缩机。

- 2

艾能空压机工艺先进、品质杰出

凭借其丰富的经验及不断创新的技术,成为全球重要的螺杆空压机供应商。在德国AERZEN公司的支持下,以及与德国著名ROTORCOMP、GHH-RAND公司的合作,使艾能空压机更上一个台阶。其卓越的主机设计,几十年的实践证明具有极其优良的性能。

- 3

艾能公司保持德国工业的精湛技术

采用德国技术,精益求精,制造的空压机极具竞争优势,广泛应用于各行各业:石化、纺织、钢铁、煤矿、水电、工程、医疗、水泥(建材)、电子、机械、汽车、食品等等,艾能空压机在中国市场已拥有良好的品牌信誉,满足了工业界对高可靠性、高效率、低能耗压缩机的需求。

- 4

艾能基于“用户至上”的策略

艾能公司在制造一流空压机的同时,更广泛提供售前和售后服务---快速、可靠、革新,以期最大程度上满足用户需求。智胜公司继续为全国范围的用户提供专业、周到、快捷的服务。

联系我们

一键拨打

一键拨打 地图导航

地图导航