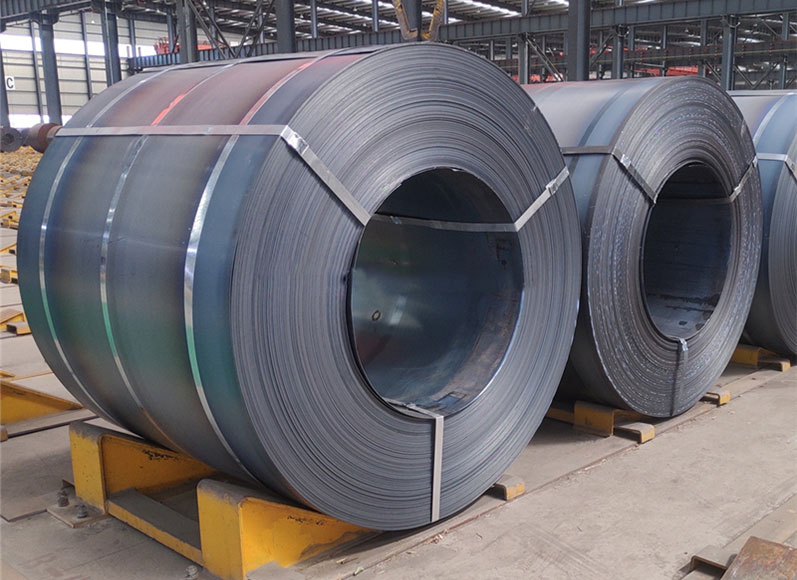

Hot rolled carbon steel coil

样本:点击下载

Hot Rolled Carbon Steel Coil Manufacturer

No cutting corners on quality and weight

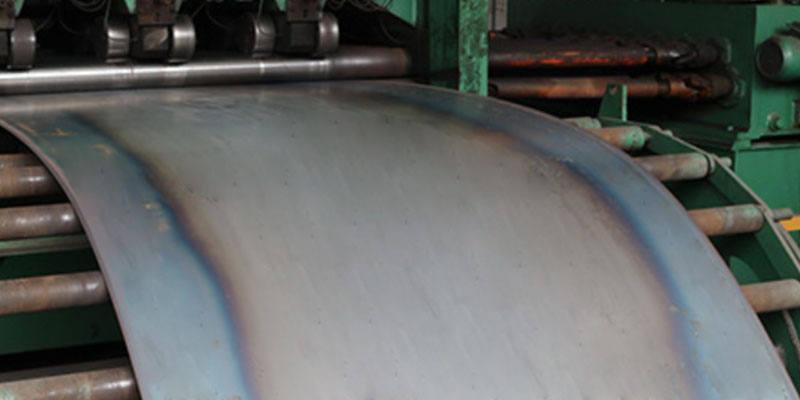

Hot Rolled Carbon Steel Coil(CRC), also known as hot-rolled coil, is made from slab as raw material and heated to produce strip steel by roughing and finishing mills. The hot steel strip from the last rolling mill of the finishing mill is cooled by laminar flow to the set temperature, and then coiled into a steel strip coil by a coiler. The cooled steel strip coil is then produced.

Hot rolled steel plate products have excellent properties such as high strength, good toughness, easy processing and good weldability, and are widely used in manufacturing industries such as ships, automobiles, bridges, construction, machinery, pressure vessels, etc.

Hot Rolled Steel Type:

Hot Rolled Steel Type:

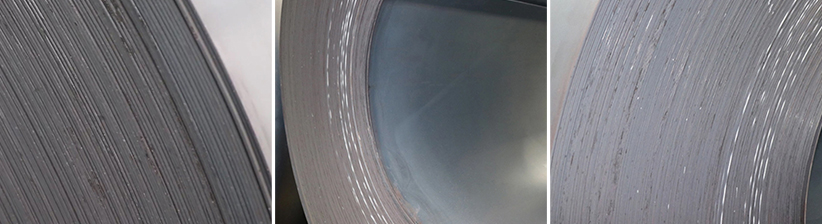

Coil/Sheet Hot Rolled Steel Surface:

Hot Rolled Steel Surface:

Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C,Q390D,Q390E,

Q420,Q420B,Q420C,Q420D,Q420E,Q460,Q460D,Q500C,Q500D,

Q500E,Q550C,Q550D,Q550E,Q620C,Q620D,Q620E,Q690A,Q690B,

Q690C,Q690D,Q690E,Q690D,Q690C,Q890C,Q890D,

16Mo3,16MnL,16MnR,16Mng,16MnDR,HG785D,S690QL,50MN

Name

Hot Rolled Carbon Steel Coil

Thickness

1.0mm-20mm or as required

Width

600-1500mm

Length

1m-12m or as required

Standard

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc.

Technique

Hot rolled

Surface Treatment

Clean, blasting and painting according to customer requirement

Material

MOQ

25tons. We also can accept sample order.

Hold Rolled Steel Advantage

High strength: Hot rolled steel coils have strong cold deformation ability, making them have high strength and excellent impact toughness, suitable for applications that require bearing large loads and pressures.

Good plasticity: Hot rolled steel coils have good plasticity and can be processed into various complex shaped components through bending, stretching, stamping, and other processing methods.

Excellent surface quality: The surface of hot-rolled steel coil is smooth and flat, without obvious defects such as oxide scale and uneven size, with a beautiful appearance and easy subsequent processing and surface treatment.

Easy to weld: Hot rolled steel coils have good welding performance and can be firmly connected to other materials or components through welding processes.

Performance Parameter

| Thickness |

Yield strength (Mpa) |

Tensile strength (Mpa) |

Elongation rate A50mm% |

180 degree bending test |

|

>1.5-2.5 |

≤290 |

≥310 |

≥38 |

D=0a |

|

>2.5-3.0 |

≤290 |

≥300 |

≥38 |

D=0a |

|

>3.0-4.0 |

≤290 |

≥300 |

≥40 |

D=1/2a |

Explanation:

1. The tensile and bending tests listed in the table are applicable to longitudinal specimens

2. The tensile test uses specimens with L0=50 mm and b=25 mm

3. The sampling plan for the bending test should be carried out in accordance with sample No. 3 of JIS Z 2204, and the test method should be carried out in accordance with JIS Z 2248

4. The hardness test shall be conducted in accordance with JIS Z 2245

5. The target value for hardness HRB is 60 ± 8. The actual value provided in the warranty certificate is not a requirement for acceptance

- 1

艾能空压机种类、规格齐全

艾能压缩机是高效、品质卓越的,凭借雄厚的技术力量和丰富的制造经验,艾能螺杆压缩机品种及规格齐全,能够满足不同用户对气体品质、气量大小、使用工况等的不同要求,主要产品有:固定式螺杆空压机、双级压缩永磁变频空压机、变频空压机、永磁变频空压机、低压力螺杆空压机、工程用移动式螺杆空压机、蜗旋式螺杆空压机、矿用移动式螺杆空压机、无油螺杆空压机、无油中高压压缩机等等。对特种行业或特殊要求,艾能公司更擅长按照用户要求定制特殊的压缩机。

- 2

艾能空压机工艺先进、品质杰出

凭借其丰富的经验及不断创新的技术,成为全球重要的螺杆空压机供应商。在德国AERZEN公司的支持下,以及与德国著名ROTORCOMP、GHH-RAND公司的合作,使艾能空压机更上一个台阶。其卓越的主机设计,几十年的实践证明具有极其优良的性能。

- 3

艾能公司保持德国工业的精湛技术

采用德国技术,精益求精,制造的空压机极具竞争优势,广泛应用于各行各业:石化、纺织、钢铁、煤矿、水电、工程、医疗、水泥(建材)、电子、机械、汽车、食品等等,艾能空压机在中国市场已拥有良好的品牌信誉,满足了工业界对高可靠性、高效率、低能耗压缩机的需求。

- 4

艾能基于“用户至上”的策略

艾能公司在制造一流空压机的同时,更广泛提供售前和售后服务---快速、可靠、革新,以期最大程度上满足用户需求。智胜公司继续为全国范围的用户提供专业、周到、快捷的服务。

联系我们

一键拨打

一键拨打 地图导航

地图导航