Aluminum zinc coated (Galvalume) steel coil is a type of steel product with a surface treated with aluminum zinc alloy, which has excellent corrosion resistance, heat resistance, and processing performance. It is widely used in industries such as construction, home appliances, and automobiles. Here is a detailed introduction:

Substrate: Cold rolled or hot-rolled steel coil.

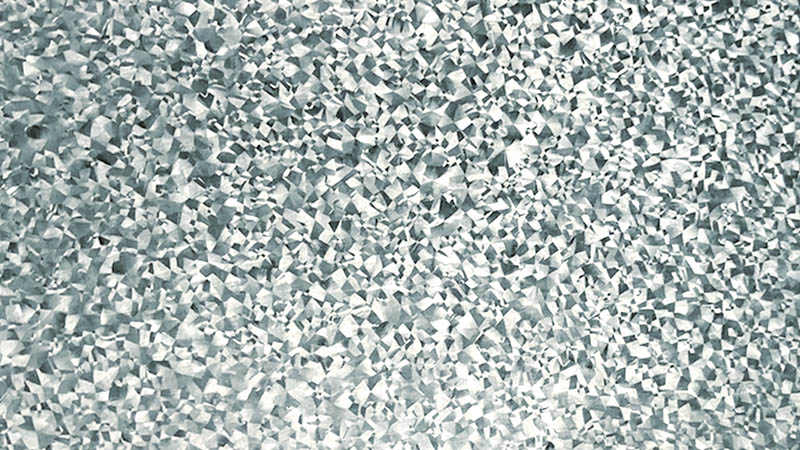

Coating: An alloy composed of 55% aluminum, 43.4% zinc, and 1.6% silicon (common models include AZ150, AZ100, etc., with numbers indicating the weight of the coating per square meter, such as 150g/m ²). The addition of silicon can suppress the reaction between the coating and the iron substrate.

Corrosion resistance: The corrosion resistance of aluminum zinc coating is 2-6 times that of ordinary galvanizing, especially in harsh environments such as coastal areas and industrial zones. Aluminum forms a dense oxide film (Al ₂ O3), while zinc provides sacrificial anodic protection.

Heat resistance: It can withstand high temperatures of 300 ℃ for a long time (up to 600 ℃ in the short term) and is suitable for high-temperature environments such as chimneys and oven components.

Reflectivity: High reflectivity (about 75% solar reflectivity), suitable for insulated roof materials.

Processability: The coating has strong adhesion and is suitable for stamping, bending, and other processing, but attention should be paid to the risk of coating peeling.

Thickness: The substrate thickness is usually 0.2-3.0mm, and the coating thickness is 10-30 μ m (e.g. AZ150 represents a total coating weight of 150g/m ², double-sided distribution).

Width: commonly 600-1500mm, customizable.

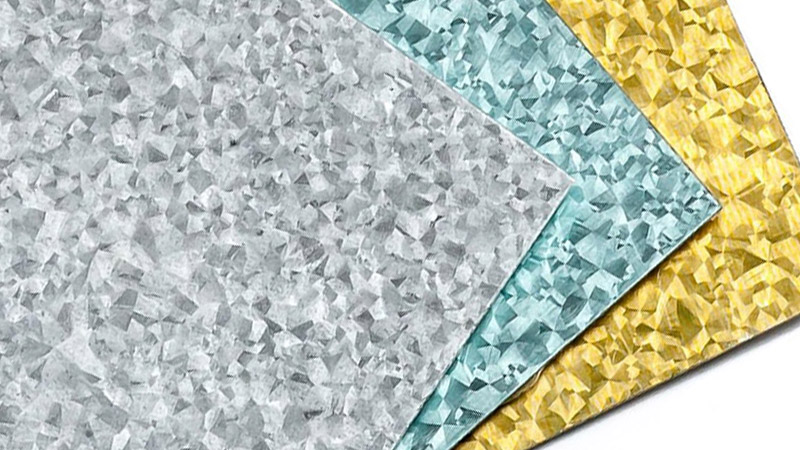

Surface treatment: Additional coatings (such as PE polyester, PVDF fluorocarbon) or passivation treatments (chromate, chromium free passivation) can be applied.

Construction industry: roofs, walls (such as color steel plates), ventilation ducts, rainwater drainage systems.

Home appliance manufacturing: air conditioning shell, refrigerator back panel, oven liner.

Automotive components: exhaust pipe, fuel tank, heat shield.

Agriculture and industry: grain silos, greenhouse skeletons, cable trays.

Characteristics:

Aluminum zinc coated steel coil

Galvanized steel coil (such as GI)

Coating composition:

55% Al-43.4% Zn-1.6% Si

Over 99% zinc

Corrosion resistance

Better(especially in acidic and high-temperature environments)

Weaker, and prone to white rust

Cost

Higher(about 10%~20% higher than galvanizing)

Lower cost

Welding performance

Requires special processes (coating is prone to oxidation)

Making it easier to weld

Cutting and welding: The cutting edge needs to be treated with rust prevention (such as painting), and aluminum zinc compatible welding materials should be used during welding.

Storage: Avoid humid environments to prevent white rust on the coating; When stacking, it is necessary to use partitions for protection.

Design optimization: Avoid direct contact with copper and stainless steel (which may cause galvanic corrosion).

Aluminum zinc coated steel coil, with their comprehensive performance, are gradually replacing some galvanized products, especially in high-end and durability demanding fields. When making a choice, it is necessary to weigh the cost and performance requirements based on the specific purpose.

English

English