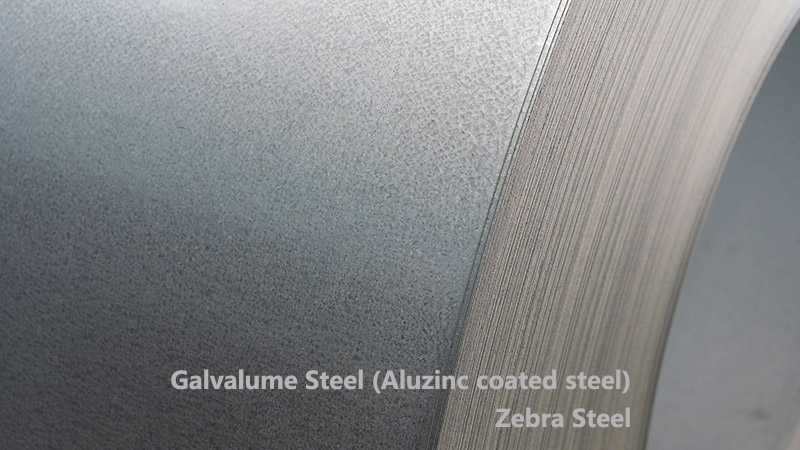

The lifespan and corrosion resistance of aluminum zinc coated steel sheet (Galvalume Steel),usually alloy coatings of 55% aluminum, 43.4% zinc, and 1.6% silicon,are closely related to coating thickness, environmental conditions, and usage methods. The following is an analysis of the impact of different layer thicknesses on performance:

1.1 The coating thickness of aluminum zinc coated sheet (Galvalume) is usually expressed in grams per square meter (g/m²) or micrometers (μm). The common coating thickness ranges are as follows:

Ordinary application: 60-150 g/m² (single-sided, approximately 8-20 μm)

Medium corrosion resistance: 150-200 g/m² (single-sided, approximately 20-27 μm)

High corrosion resistance: 200-275 g/m² (single-sided, approximately 27-38 μm)

1.2 Life expectancy estimation (in mild industrial or rural environments):

AZ60-100 g/m²: 10-15 years

AZ120-150 g/m²: 15-25 years

Above AZ200 g/m²: 25-40 years

Note: The actual lifespan is significantly affected by environmental factors such as high salt content along the coast and industrial acid rain, as well as cutting edge protection measures.

2.1 Coating thickness

Sacrificial protection of zinc layer: Aluminum zinc plated plates protect the steel substrate through the sacrificial anode effect of zinc. The thicker the coating, the longer the protection time.

The barrier effect of aluminum: Aluminum forms a dense oxide film (Al2O3), which blocks the penetration of corrosive media. High aluminum content (55%) provides long-term barrier protection.

2.2 Environmental classification

C1 (low corrosion): In a dry room, 60g/m² is sufficient.

C3 (moderate corrosion): For urban or industrial areas, it is recommended to use 120-150g/m².

C4-C5 (high corrosion): Near coastal areas or chemical plants, a minimum of 150g/m² is required, and a coating (such as PVDF) is used to enhance protection.

2.3 Other factors

Cutting edge: The cutting area that cannot be covered by the coating needs to be sealed (such as with paint or glue).

Surface treatment: Passivation or coating with organic coatings (such as fingerprint resistant films) can extend the lifespan.

Economy type: 60-100g/m² (short-term use or low corrosion environment).

Balanced type: 120-150g/m² (mostly for outdoor buildings and roofs).

Long term type: above 200g/m² (for bridges and coastal facilities), or choose aluminum zinc+organic coating composite board.

Salt spray test (ASTM B117):Aluminum zinc plated sheet (150g/m²) can usually achieve 1000-1500 hours without red rust.

Actual exposure data:Under the ISO 9223 standard C3 environment, the expected corrosion rate of 150g/m² aluminum zinc plate is less than 1 μm/year.

For more accurate life prediction, it is necessary to combine specific environmental parameters (such as Cl⁻concentration, humidity) and design specifications (such as ASTM or EN standards).

English

English