FAQ

Description of Aluminum Zinc Coated Steel Coil

Release time:2025-06-12

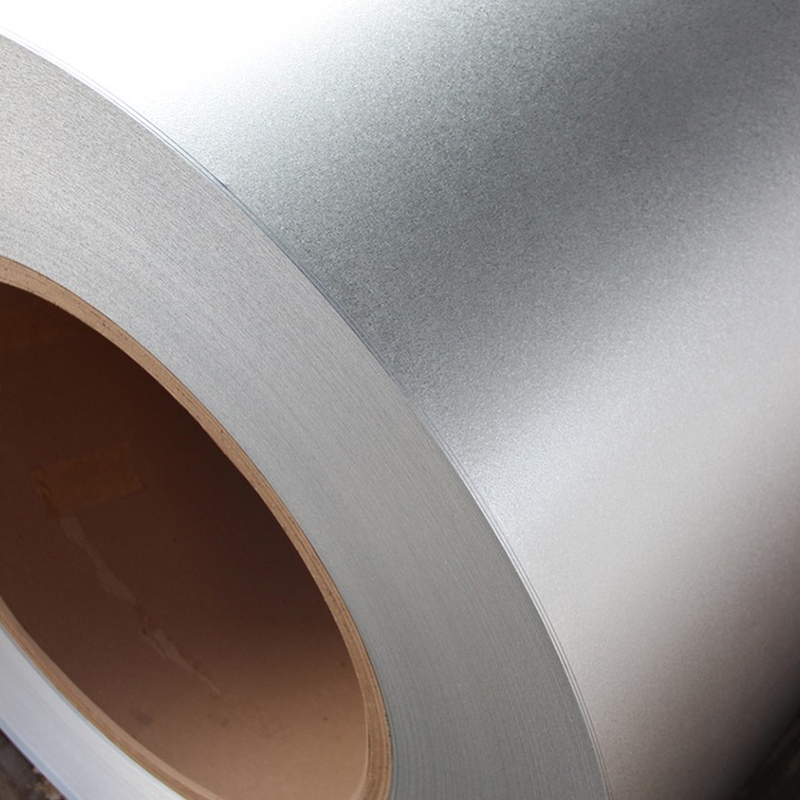

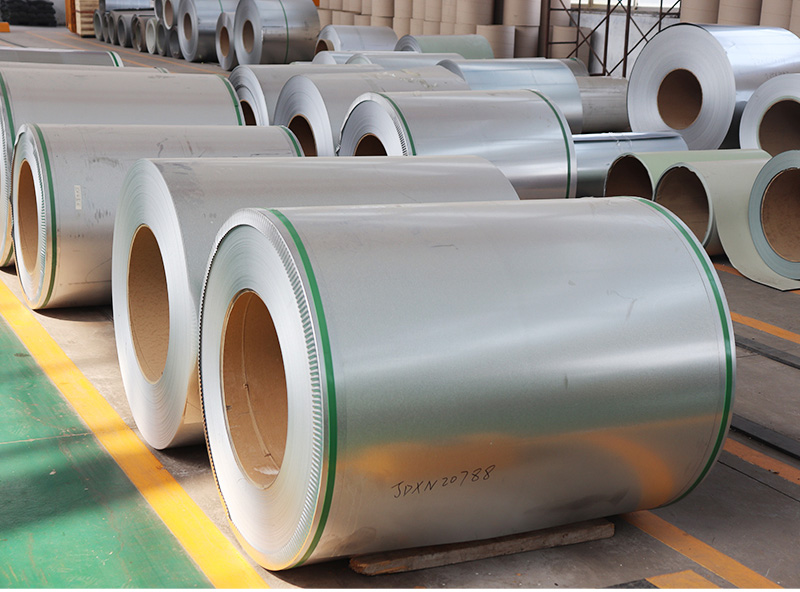

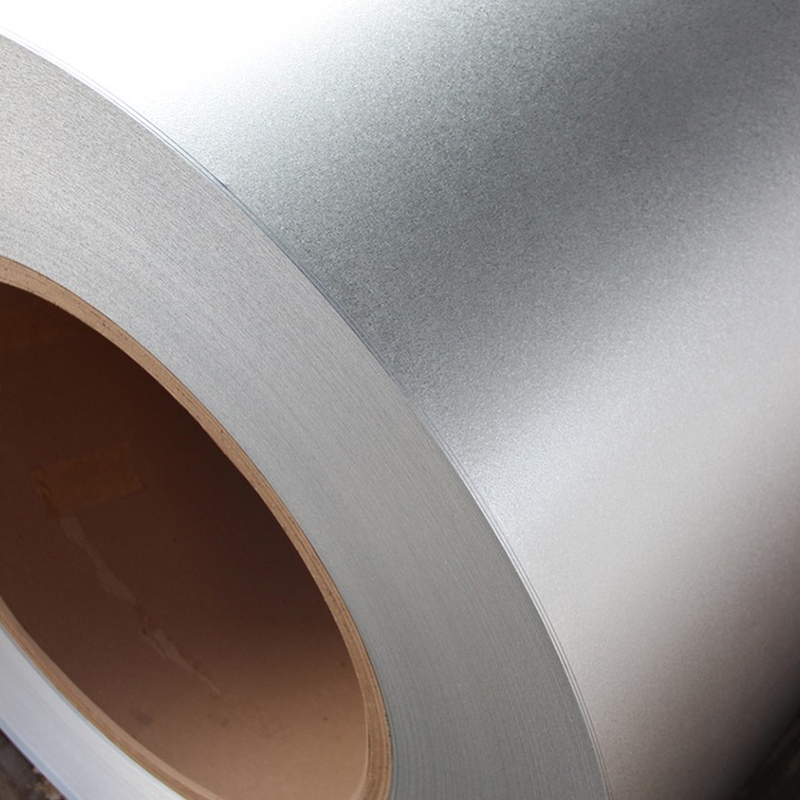

In the depths of the steel forest, a special material is quietly changing the face of modern architecture and industry. Aluminum zinc coated steel coil (Galvalume), this seemingly cold industrial product, is actually a product of the perfect combination of human intelligence and natural elements. It is not just a roll of specially processed metal, but also a silent revolution in the field of materials science, a crystallization of wisdom against the erosion of time. When ordinary steel is coated with aluminum zinc alloy, it undergoes a magnificent transformation and gains extraordinary resistance to corrosion, becoming an ideal choice for building skins, home appliance shells, and automotive parts.

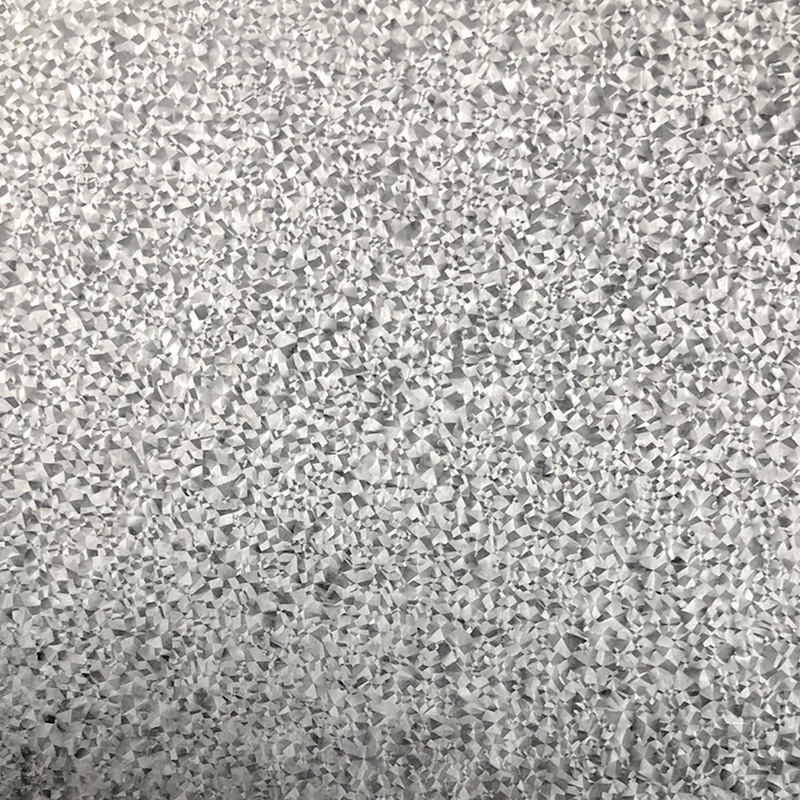

The manufacturing process of aluminum zinc coated steel coils can be regarded as a masterpiece of modern metallurgical technology. Immerse the steel strip into an aluminum zinc alloy melt pool at around 680 ℃, and through precise control of temperature and time parameters, form a metallurgical bond between the alloy and the steel base. This process combines the essence of thermodynamics, fluid mechanics, and materials science. Aluminum provides excellent corrosion resistance barrier, while zinc endows sacrificial protection function. Even if the coating is scratched, zinc will preferentially corrode to protect the steel substrate. This dual protection mechanism enables the corrosion resistance of aluminum zinc coated steel coils to reach 2-6 times that of ordinary galvanized steel plates. This characteristic is particularly valuable in coastal areas or environments with severe industrial pollution, as it allows buildings to maintain their youthfulness for a long time under harsh weather conditions.

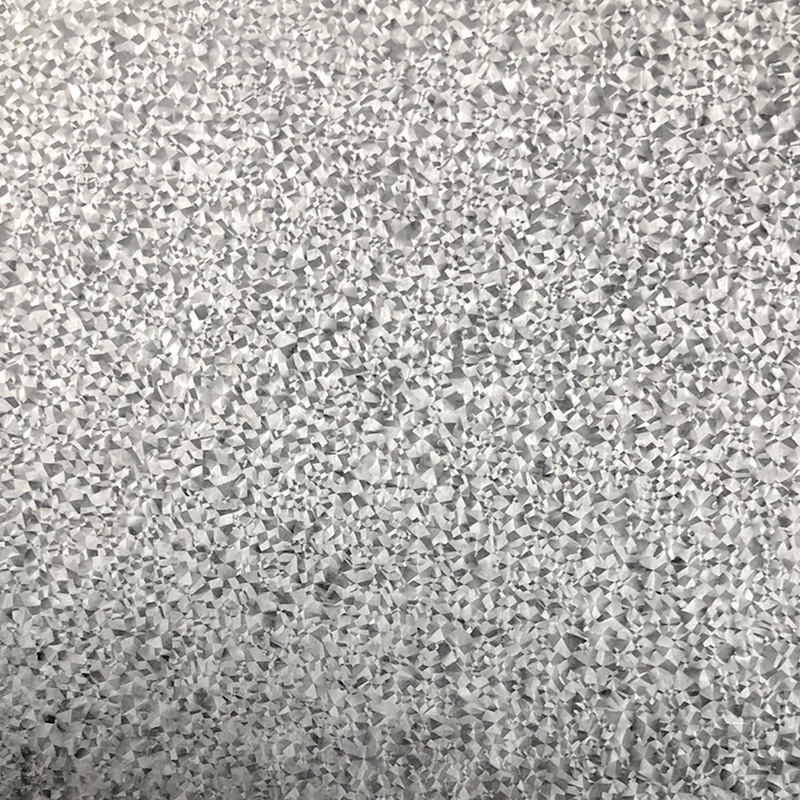

The aesthetic value of aluminum zinc coated steel coils is equally admirable. Unlike the monotonous and dull color of traditional steel, the specially treated aluminum zinc surface can present various visual effects ranging from silver white to color, providing a rich design language for modern architecture. Architects use their excellent formability to create building skins with strong three-dimensional effects such as waves and diamonds, bringing artistic vitality to originally cold and hard industrial materials. What's even more amazing is that this material forms a natural protective film on its surface over time, gradually changing color without diminishing its protective function, as if it has a life like growth trajectory. Under the sunlight, the aluminum zinc coated building facade presents dynamic light and shadow effects, adding a unique charm of the integration of technology and nature to the urban landscape.

The widespread application of aluminum zinc coated steel coils reflects humanity's profound thinking on sustainable development. Compared to traditional materials that are frequently replaced, long-lasting aluminum zinc products significantly reduce resource consumption and construction waste. At the end of its service life, it can be fully recycled, achieving a closed-loop material lifecycle. In terms of energy efficiency, the high reflectivity of aluminum zinc coated steel plates can effectively reduce the cooling load of buildings, and their lightweight characteristics also reduce energy consumption during transportation and construction. These characteristics make aluminum zinc coated steel coils the darling of the green building rating system, highlighting the possibility of harmonious coexistence between industrial civilization and ecological environment.

Standing in front of modern buildings constructed from aluminum zinc coated steel coils, what we see is not only the application of a material, but also the materialization of human collective will to resist natural erosion and pursue lasting value. From primitive thatched roofs to today's metal building enclosure systems, every leap in material technology carries humanity's pursuit of safety, aesthetics, and eternity. The story of aluminum zinc coated steel coils tells us that even in the most industrialized products, there is a profound understanding and respect for nature. When technology and natural elements are so perfectly integrated, cold metals gain a meaning beyond their physical properties, becoming another monument that records the progress of human civilization.

English

English