When choosing galvanized steel plates, it is necessary to comprehensively consider factors such as usage, environment, performance requirements, and cost. The following are the key steps and precautions:

In the field of architecture (roofs, wall panels): Steel plates that require corrosion resistance and lightweight are often selected, such as aluminum zinc plated plates (such as AZ150) or galvanized plates (such as Z275).

Home appliance casing (refrigerator, washing machine): Pay attention to surface quality and flatness, and choose electroplated galvanized steel plate (uniform coating).

The automotive industry:requires high strength and formability, commonly using alloyed galvanized sheet (GA) or high-strength galvanized steel sheet.

Pipelines and structural:components require thicker coatings (such as Z600) to enhance their corrosion resistance.

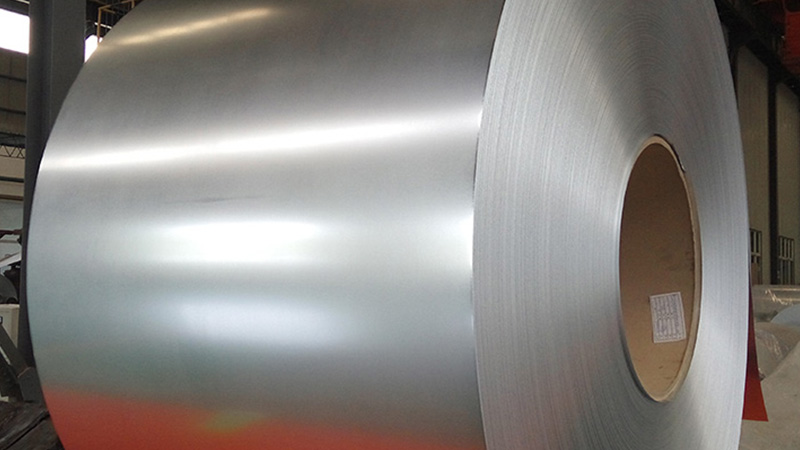

Features: Thick coating (10-50μm), strong corrosion resistance, low cost, but slightly rough surface.

Applicable: Outdoor structures, building frames, highway guardrails, etc.

Features: Thin coating (3-20 μ m), smooth surface, but weak corrosion resistance.

Applicable: Parts of household appliances, electronic products, etc. that require spraying or aesthetic appearance.

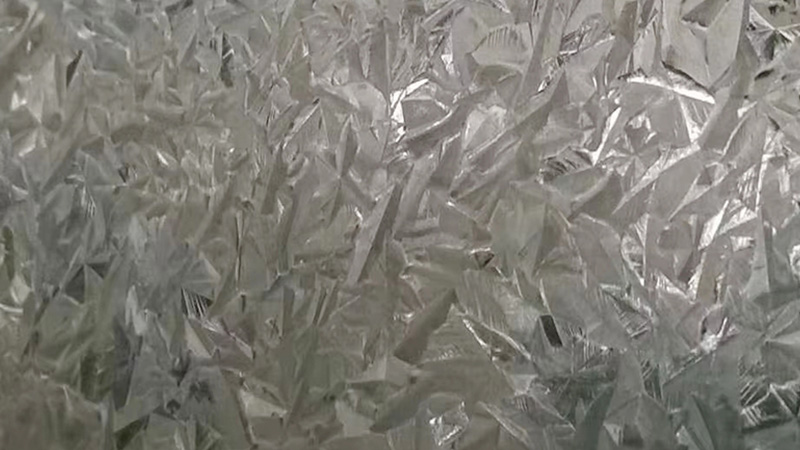

Features: Corrosion resistance is 2-6 times that of ordinary galvanizing, resistant to high temperature oxidation, but the incision is prone to corrosion.

Applicable: Roofs, high temperature environments (such as chimneys).

Features: Coating and iron alloying, good weldability and coating properties.

Applicable: Automotive panels, components that require subsequent processing.

Z60: The total weight of the zinc layer on both sides is 60g/m ² (approximately 4.2μm on one side).

Z180:180g/m ² (approximately 12.6μm per side), suitable for harsh environments such as chemical plants.

G60 (60g/m ²), G90 (90g/m ²), etc., the higher the value, the stronger the corrosion resistance.

Mild environment (indoor dry): Z60~Z100.

High humidity, coastal areas: Z120 or above or aluminum zinc plated sheet.

Ordinary cold-rolled sheet (SPCC): General purpose, moderate formability.

High strength steel (HSS): such as SGH340 (340MPa grade), used for lightweight design.

Deep drawn steel (DC04/DC06): selected when complex stamping is required.

Passivation treatment (chromate/chromium free): enhances rust resistance and is suitable for plates that require long-term storage.

Oil coating: to prevent rust during transportation, but degreasing is required before welding.

Texture: such as smooth surface, hemp surface (suitable for painting).

Environmental requirements: RoHS compliant chromium free passivation for export or electronic products.

Cost control: Electrogalvanizing is more expensive than hot-dip galvanizing, and aluminum zinc coated sheets have a higher cost-effectiveness (longer lifespan).

Quality assurance documents: Check the coating weight detection report (such as X-ray fluorescence thickness measurement).

Certification standards: ISO 9001, ASTM, JIS G3302 (Japanese standard), etc.

Recommended

Application Scenarios

Coating Weight

Remarks

Building roofs

Aluminum zinc coated sheet (GL)

AZ150

Corrosion-resistant and has a long service life

Automobile floor

Alloy galvanized (GA)

Z120

Has good weldability

Home appliance panel

Electroplated with zinc (EG)

Z60

Smooth surface and is easy to spray

Industrial warehouse frame

Hot-dip galvanized (GI)

Z180

Thick coating, resistant to harsh environments

Cut protection: The cut of aluminum zinc plated plate needs to be coated with anti rust paint.

Welding process: The galvanized layer may produce pores, and parameters need to be adjusted or GA plates need to be selected.

Transportation and storage: Avoid moisture and prevent white rust (zinc oxidation).

Through the above steps, it is possible to accurately match the requirements with the performance of galvanized steel plates, balancing durability and economy. Suggest requesting sample testing (such as salt spray testing) before purchasing in bulk.

English

English