Zinc aluminum magnesium coating products have significant advantages in the field of photovoltaic brackets and have become one of the mainstream materials. The following are its application characteristics and technological progress:

High corrosion resistance: The neutral salt spray test of zinc aluminum magnesium coated steel plate can reach 4000 hours without red rust, and the corrosion resistance is 3-5 times that of traditional hot-dip galvanizing, which can meet the service life requirements of photovoltaic brackets for more than 25 years.

Incision protection: The coating has a self-healing protective effect on the incision position, reducing the cost of post-processing for users.

Wide range of strength: Enterprises such as Pangang have achieved full variety coverage of strength levels ranging from 250MPa to 550MPa, adapting to different load scenarios.

2. Current application status

Market share: Steel brackets account for over 90% of the usage of photovoltaic brackets, with zinc aluminum magnesium coating products gradually replacing traditional galvanized steel due to their performance advantages.

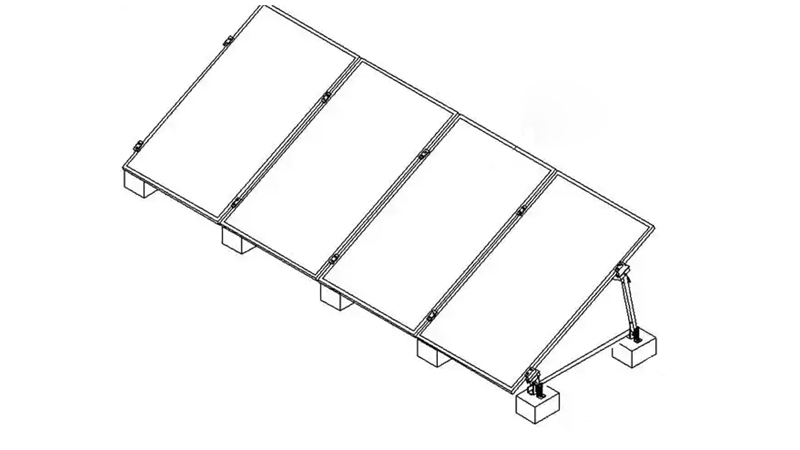

Typical scenario: Both land and water photovoltaic brackets are suitable, especially for highly corrosive environments (such as C5 grade).

According to the load requirements, the wall thickness is usually:

Lightweight bracket (span ≤ 3m): 1.2-1.5mm

Medium sized bracket (span 3-6m): 1.8-2.0mm

Heavy duty support (span>6m or high wind pressure zone): 2.0-3.0mm (such as S550GD+ZM high-strength steel)

Common materials: S350GD, S390GD, S420GD, S450GD, S550GD (tensile strength 350-550MPa)

Special requirements: Q355B (Chinese national standard) or closed steel frame (wall thickness can be as low as 0.6mm, used for component frame)

Thinning of coatings: The thickness of zinc aluminum magnesium coatings can be reduced by 50% -2/3, reducing zinc consumption and emissions while maintaining high corrosion resistance.

Policy support: The country promotes the application of green processes, and zinc aluminum magnesium coated steel plates are upgraded products that meet environmental protection and infrastructure durability requirements.

Zinc aluminum magnesium coated steel is promoting the development of photovoltaic brackets towards lightweight and long lifespan by balancing performance and cost.

English

English