The commonly used galvanized sheet thickness range for purlins is usually between 0.8mm and 3.0mm, depending on the span of the purlins, the loads they are subjected to (such as snow and wind loads), and the design specifications.

Common thicknesses: 1.0mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.5mm

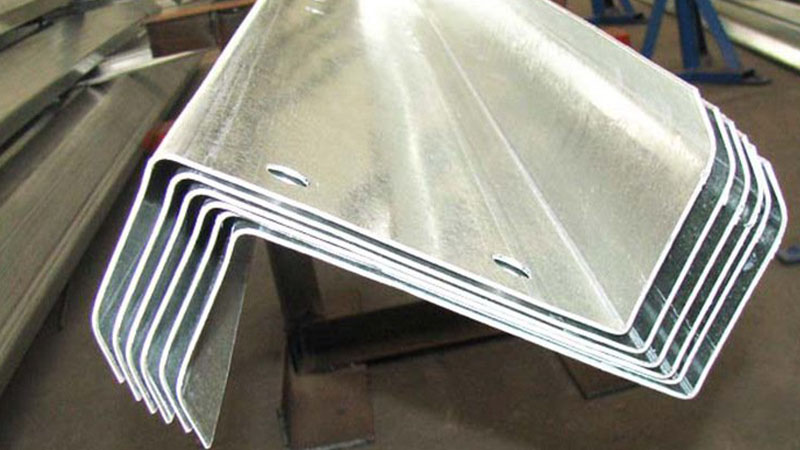

C-type purlin: commonly used between 1.8mm and 3.0mm.

Z-shaped purlins: commonly used 1.2mm -2.5mm.

The larger the span and the higher the load, the thicker the required plate thickness.

Note: The thickness referred to here is the thickness of the substrate, which does not include the thickness of the steel itself, including the zinc layer.

The width depends on the unfolded width of the purlin you want to produce. The purlin is made by rolling galvanized steel coils through a cold bending forming machine, so the width of the steel coil is the width of the flat plate after the purlin is unfolded.

Common range: usually between 200mm and 500mm, determined by the cross-sectional height and shape of the purlin.

A C200x70x20x2.0 C-shaped purlin may have an unfolded width of approximately 480mm.

A Z250x75x25x2.0 Z-shaped purlin may have an unfolded width of approximately 520mm.

You need to calculate the exact width of the raw material based on the specific design drawings of the purlins.

The zinc layer is a key indicator that determines the corrosion resistance and service life of galvanized sheet. There are usually two ways to represent it:

a) Zinc layer unit mass (double-sided)

This is the most commonly used and standardized representation method, with units of g/m². It refers to the total mass of the zinc layer on both sides of the steel plate.

Z80: indicates that the total mass of the double-sided zinc layer is not less than 80 g/m². (On average, each side is about 40g/m²)

Z100: indicates that the total mass of the double-sided zinc layer is not less than 100 g/m².

Z120: indicates that the total mass of the double-sided zinc layer is not less than 120 g/m ².

Z150: indicates that the total mass of the double-sided zinc layer is not less than 150 g/m².

Z180: indicates that the total mass of the double-sided zinc layer is not less than 180 g/m².

Z200: indicates that the total mass of the double-sided zinc layer is not less than 200 g/m².

Z275: indicates that the total mass of the double-sided zinc layer is not less than 275 g/m². (Commonly used in highly corrosive environments)

Ordinary indoor environment: Z100-Z120 is usually sufficient.

Ordinary industrial plants and coastal areas (not directly facing the sea): It is recommended to use Z150-Z180.

Highly corrosive environments (such as chemical plants, coastal areas, high humidity areas): It is recommended to use Z200 or Z275.

b) Zinc layer thickness (single-sided)

Sometimes the thickness of the zinc layer is also used to express it, with the unit being μm (micrometers).

Conversion relationship: A zinc layer mass of approximately 7.1 g/m² corresponds to a thickness of 1μm.

Z120 (double-sided total weight 120g/m²) ≈ single-sided zinc layer thickness of about 8.5 μm.

Z275 (double-sided total weight 275g/m²) ≈ single-sided zinc layer thickness of approximately 19.4 μm.

When you purchase raw materials for producing galvanized purlins, you need to provide the following information to the supplier clearly:

We need to purchase galvanized steel coils with [thickness] x [width], and the zinc layer grade is [e.g. Z150]. ”

We need to purchase galvanized steel coils with a thickness of 1.8mm and a width of 480mm, with a zinc coating grade of Z150. ”

English

English