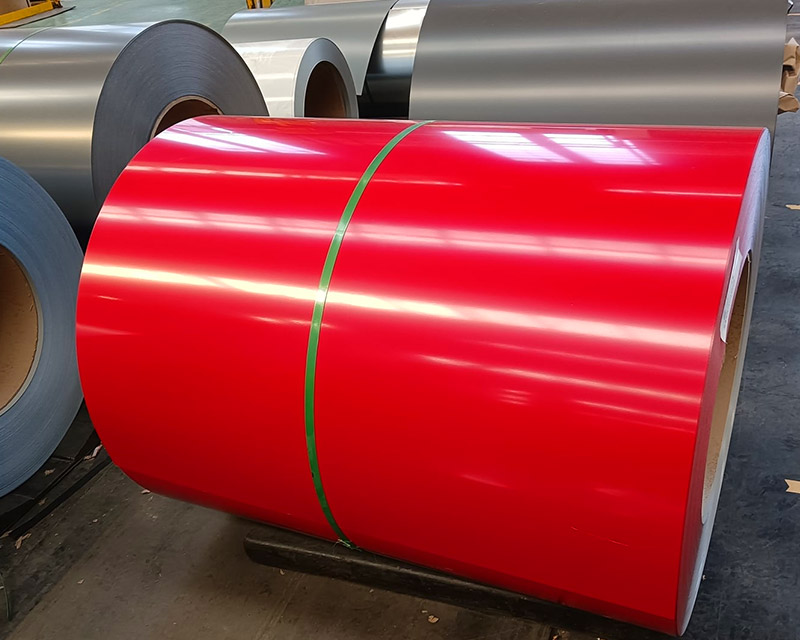

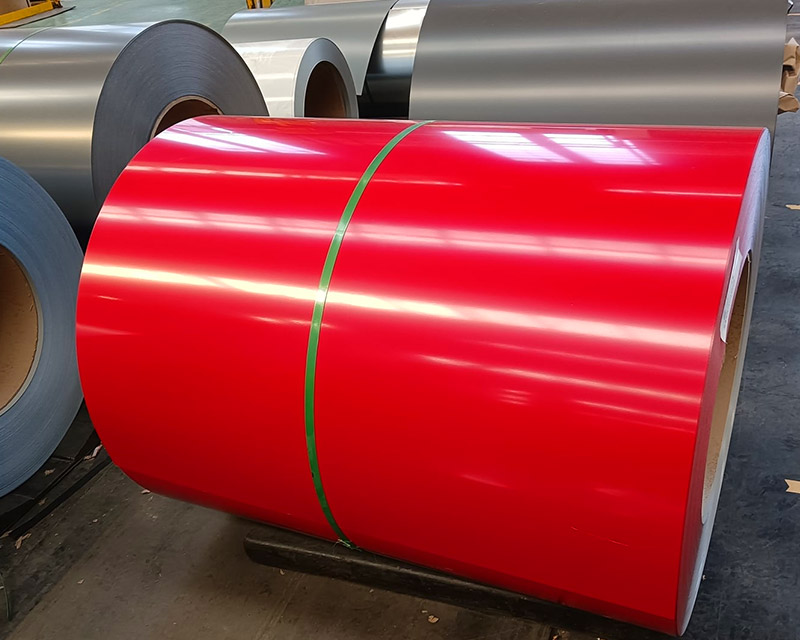

1、 Precautions for purchasing color coated steel coil Prepainted Galvanized Galvalume Steel Coil(PPGI PPGL)

Substrate material

Common substrates: galvanized (GI), aluminum zinc plated (GL), cold-rolled steel plate, etc.

The weight of the galvanized layer (such as Z60, Z180) affects corrosion resistance and needs to be selected according to the environment.

Coating type

Topcoat: Polyester (PE), Silicon Modified Polyester (SMP), Fluorocarbon (PVDF), High Durability (HDP), etc. Different coatings have significant differences in weather resistance and durability.

Primer: epoxy resin, etc., ensuring adhesion.

Thickness and tolerance

The total thickness includes the substrate and coating. The common substrate thickness is 0.2~1.2mm, and the coating on one side is usually 15~25 μ m.

Require suppliers to specify thickness tolerances (such as ± 0.02mm).

Color and surface treatment

The color should comply with international standards (such as RAL, Pantone) to avoid color differences.

Surface texture (glossy, embossed, etc.) affects aesthetics and performance.

Corrosion resistance and weather resistance

Salt spray test (such as 1000 hours), UV aging test and other data must meet the standards, especially for coastal or industrial areas.

Packaging and Transportation

Moisture proof paper+steel strip bundling to avoid edge damage, rust proof treatment is required for sea transportation.

2、 Common specifications and dimensions of color coated steel coil PPGI PPGL

Thickness

Substrate thickness: 0.2~1.2mm (commonly used 0.3mm, 0.5mm, 0.8mm).

Total thickness: substrate+coating, usually increased by 30-50 μ m.

Width

Conventional: 600-1300mm (customizable to 1500mm or above).

Standard widths: 1000mm, 1200mm, 1250mm.

Roll weight and inner diameter

Roll weight: 3-10 tons/roll (varying in thickness and width).

Inner diameter: 508mm (20 inches) or 610mm (24 inches).

3、 The main application areas of color coated steel coils

construction industry

Roofs and walls (such as steel structure factories, airports, sports halls).

Sandwich panels, corrugated panels (insulation requirements).

Home appliance manufacturing

Refrigerator, air conditioner casing, washing machine panel (requiring high gloss or antibacterial coating).

Transportation

Car partition and container shell (required to be wear-resistant and corrosion-resistant).

Furniture and Decoration

Indoor partitions and ceilings (emphasizing aesthetics and environmental friendliness).

other

Solar panels, billboards, ventilation ducts, etc.

4、 Additional suggestions

Sample testing: Request samples in advance to test performance such as bending, impact, color difference, etc.

Contract details: specify technical parameters and delivery time.

Inventory matching: Avoid cutting waste caused by unconventional sizes.

Through the above points, high-quality color coated steel coils can be effectively screened to ensure a balance between project requirements and cost control.

English

English